Wood and cotton!! How similar are they ?

In the last article of natural materials I wrote about woodpeckers and seashells, but there a lot more natural materials which we come in contact with in everyday life. One of the most common one being wood, there are many forms of it and all of them exist in nature as composite material. Composite materials are formed by combining two or more materials that have quite different properties; they do not dissolve or blend into each other. Most of you must be familiar with the concept composite materials, but you might be surprised when I tell you that wood and cotton are both made of cellulose. Cotton is made of cellulose in the form of long fibers, but it has no other material binding it, whereas wood also has cellulose fibers, but these fibers are bound together with lignin [2].

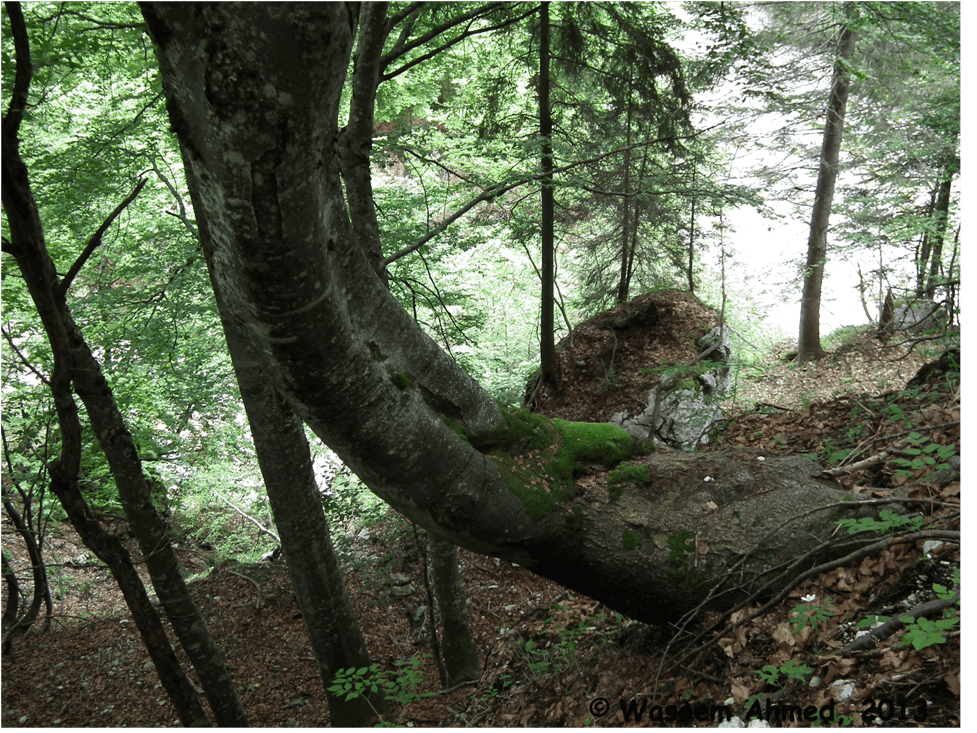

In ‚Figure 1‘ you can see that the tree grows comfortably even on a steep slope, the reason for that is that trees add materials where needed to provide additional strength. Well that is smart, but is that it? The answer is no, the method of adding material is by adding fibers in the direction of the force for additional strength in that direction. Trees use this method for coping with different kinds of stresses both arising from their own weight and also the forces exerted by external sources. This method of adding fibers in the direction of the loads is being extensively used in modern day construction and design of composite materials for automobiles, planes, turbines etc.

Spider silk, is it really strong??

We keep hearing from many sources that spider silk is stronger than any of the synthetic materials today, this is true but to a certain extent. The strength of spider silk can be compared to some high grade steel alloys (450-1970 MPa), but compared to Kevlar it has half the strength. But it does not mean that you were wrong about the uniqueness of spider silk, when you look at the density and toughness of spider silk there is none to compare it to. The density of spider silk is 1.31 g/cm3 [1]which means you can have a spider web a few kilometers long but still weigh less than a kilogram. Spider silk is also extremely ductile in nature and it can extend up to five times its length without breaking. When it comes to toughness (toughness simply refers to the work needed to fracture something) of spider silk the combination of strength and ductility makes it an extremely tough material. The image below shows how a small web is able to with stand the weight of a large spider.

Not only is the spider web tough, but it is also optimized. During my master in one of my projects I had to research if the spider webs are optimized or if there is room for human optimization. In this project I took pictures of real spider webs and transferred their geometry into a computer simulation with the help of CAD software(shown in figure 3). In order to compare and test the spider webs I simulated them with different loading conditions which they might face in the real world and surprising there was no room for optimization. Such unique combinations of design and material selection in nature can be used as an inspiration for designing applications like security nets on high rise buildings or as endoskeletons in construction for giving additional core strength.

This is the end of the topic natural materials for now, next Tuesday my collegue will talk about yet another interesting bionic topic.

References

- Griffiths, J. R.; Salanitri, V. R. (1980). „The strength of spider silk“. Journal of Materials Science 15 (2): 491–6.

- Forest Products Laboratory (US). Wood handbook: wood as an engineering material. No. 72. United States Government Printing, 1987.