For the theme session of WOOD, we will discuss the properties of tree wood and factors which influence these properties. Wood is a natural composite that exhibits a remarkable combination of strength, stiffness and toughness [1]. At the same time being a natural/organic product, it is a structure of infinite variation of detail and design. It is due to this reason that no two specimens of wood log are alike, in spite of being harvested from the same tree. Though species of trees can be characterized based on physical features, they are still many considerable variations when it comes to wood. Detailed studies have established that the unique hierarchical architecture in wood is one of the most influential factors for it achieving its properties [1]. Wood facilitates thermal insulation, mechanical stability, water transportation, self healing and fire resistance among many other functions in trees.

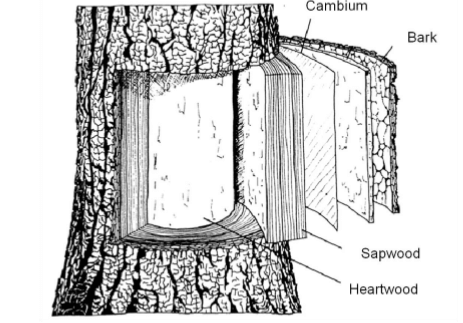

Figure 1: Schematic representation of wood layers within a tree trunk.

Wood was recognized as a natural composite as early as 1980. In the former biomimetic study, Gordon and Jeronimidis extensively studied the tracheid of timber, and successfully applied the energy absorption mechanism of wood cells under tension in engineering composite materials to increase the work of fracture [2].

So what makes wood dissimilar to each other ? And more importantly, how does this variation affect the mechanical properties?

Each tree is influenced by different environmental conditions like light, water and nutrition [3]; additionally mechanical loads such as wind greatly affect the properties of wood. In a natural environment, the trees always find a compromise between strength, water transportation and nutrition storage. The optimal ratio between these three main functions will lead to the appearance of a single tree and the mechanical properties of its wood. Besides this, the genetic material affects the form of the tree and the wood itself. All these functions have developed over a long period of evolution.

Figure 2: (a)Tree growing on an inclined (b) Sequoia Sempervirens (Coast redwood)

In Figure 2, both trees have emphasis on different functions, in simple words both got their own set of problems. The tree on the left has to provide a greater mechanical stability since it grows on a slope. Though water transportation and collecting sunlight are equally important, in this case the mechanical strength has a larger priority. While the tree on the right also requires greater mechanical stability, it allocates higher focus on water transportation since it has to pull water to greater heights .

Mechanical properties:

Wood is an organically grown, an-isotropic and non homogeneous material. In the inner structure of wood, fibers orient themselves in axial and radial directions which is the reason for an-isotropic material properties (shown in figure 3(a). Wood also has different properties depending on the directions it is cut. There are cross sections and longitudinal cuts, differentiated into radial (from the core to the bark) and tangential (across the middle of the stem) [4]. These three different directions are shown in Figure 3(b), because of these three cut directions solid wood is assumed to have orthotropic material properties.

Figure 3: (a) Fiber orientation in wood cell wall (b) Cutting directions of wood

Wood basically consists of three molecules which serve as cell walls. Below are those three molecules and their function.

- Cellulose – Absorbs mechanical forces, especially tensile loads

Composed of long chains of glucose units cellulose fibres provide high tensile strength to the cell walls. The long fibrous molecule chains are bound together to so-called fibrils running around the cell wall like a screw [4].

- Lignin – Absorbs compression loads; intercellular cement.

Lignin (Latin word lignum meaning wood) doesn’t consist of long chains like cellulose; its building blocks are combined together in a three-dimensional molecule. It is a non-structured filler comparable to concrete. The compression strength increases by a higher lignin content[4].

- Hemicellulose – Intercellular cement.

The cell wall in wood also contains other carbohydrates, called hemicelluloses. These molecules are short-chained.Their function is to be a binder or fastener between the cellulose and the lignin.

As mentioned above, the strength and deformation behavior of wood depends on the growing conditions of wood. When loaded parallel to the fiber, we can evaluate differences in tension and compression loads. During compression the fiber will buckle, but during tension wood exhibits brittle behavior. The tensile strength is double as high as the compression one [3]. The difference for tension and compression strength is due to the arrangement of the cellulose fibers and their crystalline structure and the matrix made of lignin.

The micro architecture in tree wood is comprised of small cracks. The microscopic cracks absorb the energy under stress, while the whole structure remains intact. This has to be considered if a wooden structure is to be loaded above its yield strength.

Figure 4: Cracks in wood

Moisture content:

The water ratio is an important factor in wood. It influences the density, the weight, the strength, the electrical properties and the durability. Solid wood cannot hold its dimension while the ambient humidity changes [6]. The water content in wood changes after cutting the tree, during the manufacturing until the implementation of the structure. The swelling and shrinking caused due to this happens in three directions – parallel, radial and tangential to the stem axis. For this reason, timber is normally sprinkled in saw mills to make sure that the wood will dry slowly from inside to outside. If this process happens slowly, less fracture and deformation will occur.

Thermal Conductivity:

Thermal conductivity of wood and the variables affecting it are of utmost importance from the standpoint of building insulation. Wood is used in industries and homes where the resistance of wood to heat transfer is of huge significance. Wood is influenced by many factors in terms of heat conductivity. Some of the more significant variables affecting the rate of heat flow in wood are:

- Density

- Moisture content

- Direction of heat flow (with respect to the grain orientation).

- Distribution of extracts (chemical substances) like gums, tannins, or oils.

- Defects (checks, knots and cross grain) [6&7].

Additional reading

To conclude, wood facilitates multiple functions in trees. The mechanisms how wood in trees adapts to environmental conditions provides valuable insight for designing smart and sustainable composite materials. Additionally, knowing the influential factors in shaping the properties of wood is essential to choosing the right wood. If you have thoughts, comments or questions, feel free to write to us 🙂

Figures :

-

(2017). Edok01.tib.uni-hannover.de. Retrieved 24 March 2017, from http://edok01.tib.uni-hannover.de/edoks/e01fb02/357010868.pdf

- (a) Author- waseem ahmed

(b) File:General Sherman tree looking up.jpg – Wikimedia Commons. (2008).

Commons.wikimedia.org. Retrieved 24 March 2017, from https://commons.wikimedia.org/wiki/File:General_Sherman_tree_looking_up.jpg - (a) Niemz, Holzphysik (Skript zur Vorlesung), [Ed. 2006, September] ed. Zürich: ETH, EidgenössischeTechnischeHochschule Zürich, 2006.(b) Credits: Cornelius Tormann

- (2017). Static.pexels.com. Retrieved 24 March 2017, from https://static.pexels.com/photos/40973/background-brown-circle-cut-40973.jpeg

- Featured image: (2017). Static.pexels.com. Retrieved 24 March 2017, from https://static.pexels.com/photos/7557/wood-sun-forest-evening-7557.jpg

References:

- Li, S. H., et al. „Biomimicry of bamboo bast fiber with engineering composite materials.“ Materials Science and Engineering: C2 (1995): 125-130.

- E. Gordon and G. Jeronimidis, Phil. Tram. R. Sot. Lon., A 294 (1980) 545.

- Niklas, Karl J. Plant biomechanics: an engineering approach to plant form and function. University of Chicago press, 1992.

- K. Götz. (2002). Technisches Holz nach dem Vorbild der Natur Abschlußbericht zu dem durch das BMBF geförderten Vorhaben mit dem Förderkennzeichen 01 RP 9804/9 ([Elektronische Ressource] ed.). Available: http://edok01.tib.uni-hannover.de/edoks/e01fb02/357010868.pdf

- Niemz, Holzphysik (Skript zur Vorlesung), [Ed. 2006, September] ed. Zürich: ETH, EidgenössischeTechnischeHochschule Zürich, 2006.

- Bauer, Georg, et al. „Insulation capability of the bark of trees with different fire adaptation.“ Journal of Materials Science21 (2010): 5950-5959.

- (2017). Fpl.fs.fed.us. Retrieved 24 March 2017, from https://www.fpl.fs.fed.us/documnts/pdf1941/macle41a.pdf